The Hubei Shiman Highway Project (Shiman) is an expressway which I am supervising for the World Bank, under construction in the NW corner of Hubei Province. A 105.1 km long road running from the city of Shiyan, it travels west towards Shaanxi province, ending at Manchuangan. Crossing mountainous terrain with about 40% of the road tunnels and bridges, it is an incredibly challenging project from an engineering point of view.

Twice a year I perform a supervision mission, accompanied by my various specialists. Since the project started in November 2004 they have made great progress and where there was once virgin territory we now see the infrastructure of a great highway rising. My wife Lis finds this quite disturbing, as she is morally opposed to development raping and pillaging the landscape, but I see the great benefits that will come from linking up the cities in China with a safe and efficient highway network. Let’s just say that we agree to disagree on this ..

As an example of what I mean about the impact of the expressway, consider the photos below which are typical of the project.

At this stage of the construction there are four major components:

- Earthworks: which consist of the sub-base of the highway (see the photo above);

- Bridges and Culverts: which take the highway over obstacles or ensure no sudden changes of gradient;

- Tunnels: what you do when you can’t go around something; and,

- Slope Stabilization: Keeping the mountain sides from falling on you when you’ve made a cut through them.

Earthworks are basically easy. You get big machines and move earth (well, there is a bit more to it than that … but not much) but it is the others which are fascinating, especially how they do it here in China.

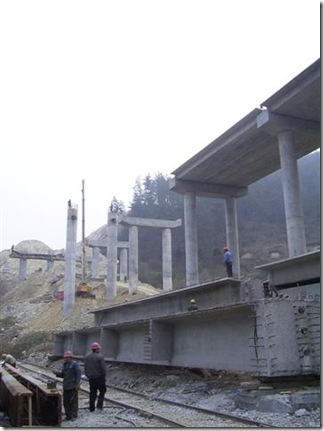

Crossing through the deep valleys we have some very high viaducts, some 60 m in the air. The photos below give an idea of what we are building.

The construction of the viaducts consists of three basic steps. First, you need to get the foundation in place. Once this is done, you can then pour the columns from concrete. Finally, you put in place the beams at the top upon which the road rests.

Let’s say that you want to put down a foundation for a 60 m high viaduct. In the west we have machines which will bore into the soil and do all the work. Not in China. Here, the solution is much simpler. They give some workers a shovel and tell them to dig a hole. You don’t believe me? Have a close look at the photo below. You will see the fellow at the top of the foundation hole with a basket of rock which he has just raised up from the worker at the bottom who is working with hand tools. This is a sophisticated set up insofar as they have an electric winch for raising the rocks; in other locations it was a hand winch, kind of like you see on a wishing well.

I don’t mean to be critical of this approach, quite the opposite. I think that it is amazing what the Chinese can achieve through strong arms and strong backs. There is a real need in China to create jobs, and doing as much as possible by hand helps to absorb the unemployed rural workers into the workforce. It is also a good deal for the contractor. The labourers earn about $3 a day (I asked them) so if it takes 3 months to do a foundation with two workers that is only $600. And I bet they are a lot faster than that.

The conditions for digging foundations can be very unpleasant. I took the photo below at a site where the soil was very wet and mucky. You can see the worker carrying away bucket after bucket of soil. But this wasn’t the worst of it. At the bottom of the foundation a worker was going at a rock with a pneumatic drill. The noise was unbearable at the surface, and there was clouds of dust rising from the hole. I doubt that he had very acute hearing by the time he was through with things.

In spite of being dug manually, the final product is excellent. They are vertical, with a constant diameter all the way down, and once lined with concrete you would not know how they were done. In fact, my Spanish consultant didn’t believe me when I told him how they were dug. Hopefully he will now that I have the photos ![]()

Our project has one particular challenge: the Han River. This is one of China’s major rivers and we are putting a bridge across it. Foundations here are of course much more challenging as you have to put down caissons, keep them dry, and remove the soil. They have a very efficient process where they have small cement mixers on barges which take out concrete to the works in the river, and a pump for the ones closer to shore, but the logistics are very difficult to manage. Especially when the province upstream decides to open the sluice gates on their dam without warning, causing the river to rise by 6 m in the matter of hours. That served to wash away the barges and a lot of the works. Ho hum.

Once the foundations are down you put up the columns. this is done by tying together a steel frame, putting it in place vertically, placing form work around the frame, and pouring concrete.

As with the foundations, they used relatively unskilled labourers for much of this work. They are taught the simple task of how to tie together the steel (it doesn’t take much as the concrete provides all the bonding strength) and they go to it. The end result is very good and consistent. The larger challenge is getting the formwork correctly in place, but again they have tended to achieve this. I have only heard on one instance where a mistake was made and they needed to cut the column and redo the work. Now that is an expensive mistake.

The concreting takes real skill. You need to pump it in and vibrate it so that there are no air voids. You need to be careful not to over-vibrate it as that can compromise the integrity. A sign of good quality control is where the concrete is a consistent colour up the entire length of the columns. Some contractors acheived this with amazing consistency.

The final piece of the puzzle are the beams which go out horizontally and rest on the columns. These are cast out of concrete in a ‘casting yard’ and then launched to rest on the columns. The beams are ‘post tensioned’. This means that when they are cast there are hollow tubes that pass along the length of the beam. High strengh steel strands are passed through the tubes and connected to a hydraulic jacks. These put a certain amount of tension on the strands which are then anchored. Grout is then pumped in to fill the tubes. This pre-compression of the beam counterbalances the forces put on the beam by the traffic, significantly increasing the load bearing capacity.

In some locations the casting yard was built at one end of the bridge. The beams were ‘launched’ by building a small ‘railway’ which a crane straddles. The crane lifts the beam and moves along to the end from where it is launched horizontally. What is more impressive is when there is no space and they have to launch them from below. In this instance you get a very massive crane, capable of lifting very heavy weights to a great height. The photos below show such a beast, the size of the beams and the height they are launched to. It will probably come as no surprise that women make the best crane operators. They are capable of fine movements men have difficulties with. (BTW: in the top photo you can see the post-tensioning cables sticking out from the end of the beam).

Enough of bridges. Let’s talk tunnels.

I am not ashamed to say that prior to this project I knew absolutely nothing about tunnels. New Zealand does not have a single road tunnel. Now, I know a very little bit about tunnels, enough to be impressed with those who build them.

During construction tunnels are cold, noisy, dark and damp (or downright wet if you break an aquifer as one of ours did). Even though we require ventilation of tunnels, this is not always done or there is simply not enough air being pumped in. Consequently, they are not pleasant places to work. They are always tidied up for Bank mission visits so we see them at their best. I’d love to see them during an un-announced visit.

Our project is very fortunate to have James Allison as the team leader for the construction supervision team. James is a mining engineer who learned his trade in West Australia. There are a variety of different tunneling approaches used and this project uses what is called the ‘New Austrian Tunneling Method’ (NATM). The basic concept is that you use the strength of the surrounding rock mass as the main component of tunnel support. They dig the tunnel in different ways depending on the type of material encountered. Blasting is, of course, and important element of the process.

As you have probably guessed by now, the tunnels are dug by hand, not using machines as we usually do in the west. Again, this is a very rational choice of the contractors. After all, they have 3 years to dig 3.1 km. Why rush it if you can spend less money and do it all by hand?

All of our tunnels have two tubes, one for carrying the traffic in each direction. They start by digging a small pilot tunnel between the tubes, which is given a reinforced concrete structure in the tunnel. This forms part of the structure of each of the two tubes. They then excavate outwards and downwards, using ‘shotcrete’ (a type of pumpable concrete which sticks to walls) on the inside of the excavated tunnel. They seem to be able to manage about 3 m a day when all goes well, but then problems invariably arise which slows them down. For example, we’ve encountered faults, major changes in rock type within a few metres, and even had some collapses, but fortunately no deaths as a key part of NATM is to monitor deflections so they know what was coming …

Finally, let’s look at slope stabilisation. This is very important as we often cut our way through hillsides and so have very high embankments. During the design stage we noted that some proposed cuts were 70 m vertically (which is VERY high) and we insisted that they not exceed 50 m (still quite high). The soils in the area where we are building the highway are often quite poor so they have had problems in a few areas, and I saw a text-book example of shear failure where an entire hillside slumped.

Having said that, the Chinese generally do excellent slope stability work. As with everything else, it is very labour intensive but they excel themselves even further by using waste material: rock. Most of the stabilization is done using hand-laid rock faced retaining walls as shown in the photo below. Higher up they use reinforced concrete for extra strength, but most of the material is rock which has been excavated elsewhere on the site.

They are masters of economy. In the photo below you can see how they are using excess rock to bond two layers of concrete. Why spend money on reinforcing steel if you can use rock for free? For reasons such as this, the roads cost a fraction to build in China as they do elsewhere, even allowing for the different labour costs.

It is impressive to see them put up a 10 m high wall, entirely made from stone, where the only tools they have are chisels, buckets of cement, and a plumb-bob comprised of a stone hanging by a string. If you didn’t see them doing it, you wouldn’t believe it was possible.

This is a good place to end. I hope that this has given you a small appreciation of both the challenges of expressway building in China, but also the truly impressive way the Chinese are going about it. I consider myself particularly blessed to have the opportunity to work on a project such as this. As an engineer it is a once in a lifetime chance, for which I will always be grateful.

Posted by triduffer

Posted by triduffer